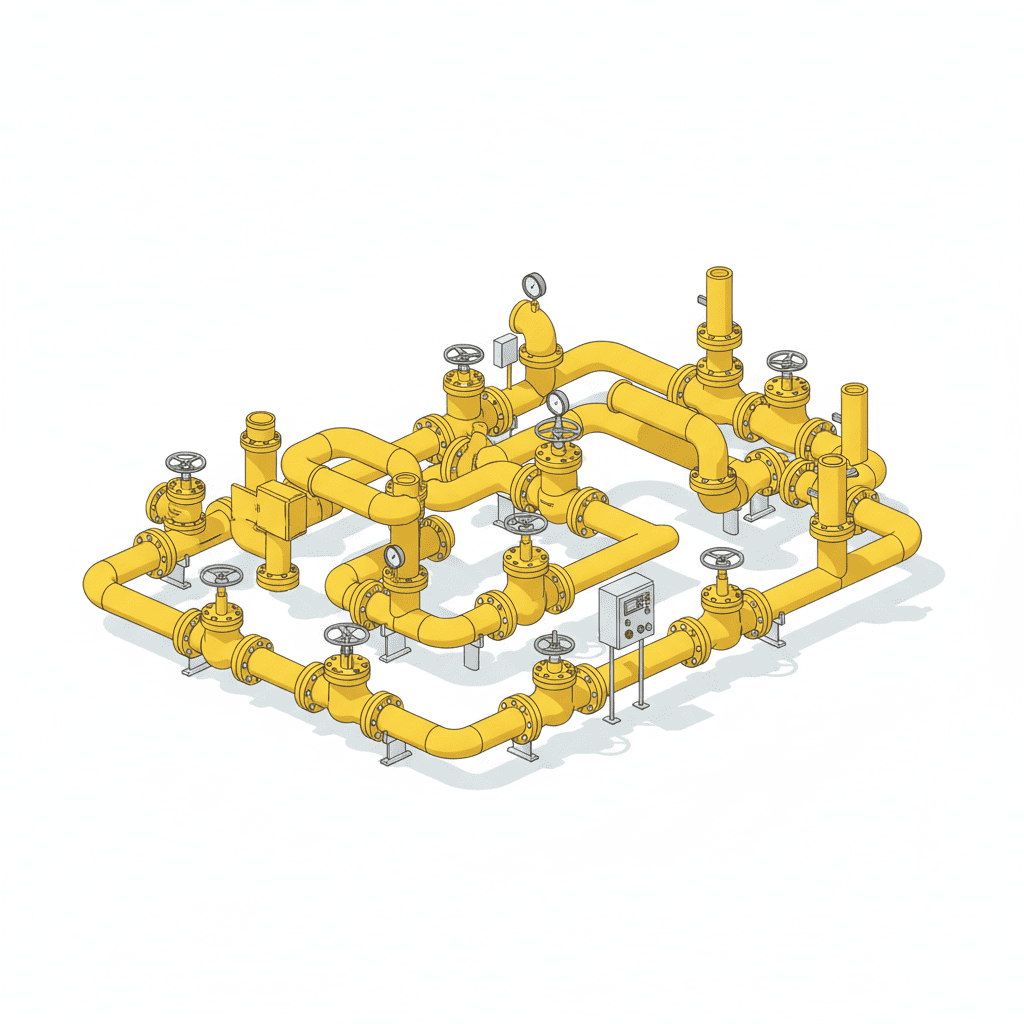

Our Service

Ensuring Your Gas Pipework is Leak-Free

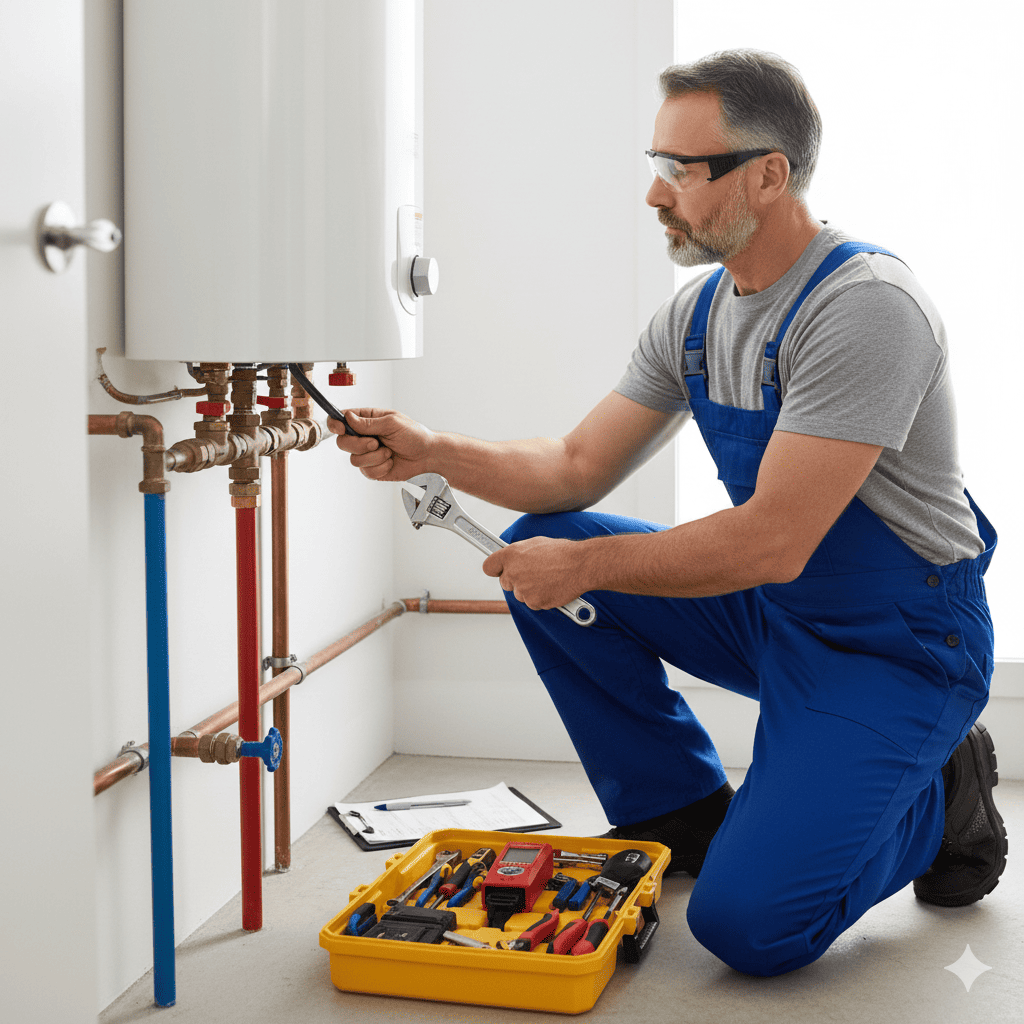

Commercial gas pipework is the lifeline of your heating system, but it also carries significant risk. Even a tiny leak in large-diameter pipes can lead to disaster. At Safety Property, we provide specialized CP16 testing and purging services. Whether you are commissioning a new installation or decommissioning an old one, we ensure your pipework is safe, tight, and compliant with IGEM/UP/1 standards.

Why Choose Safety Property?

IGEM Certified: Our engineers are fully trained to standards set by the Institution of Gas Engineers and Managers.

Precision Equipment: We use calibrated digital manometers and purge fans to handle high-volume systems safely.

Full Documentation: You receive a comprehensive CP16 certificate detailing the strength test and tightness test results.

Service Standards:

Strength Testing: We verify that new pipework can withstand operating pressures without failing.

Tightness Testing: We detect even the smallest drop in pressure that indicates a leak.

Safe Purging: We safely displace air with gas (commissioning) or gas with air (decommissioning) to prevent explosive mixtures.

Prevent Explosions

Mixing gas and air in a pipe creates a highly explosive atmosphere. Our professional purging process strictly controls velocity and volume to remove this risk entirely during installation or removal.

Legal Compliance

Under the Gas Safety (Installation and Use) Regulations 1998, all commercial pipework must be tested for tightness. A CP16 certificate is your legal proof that the system is secure.

Leak Detection

Old pipework can corrode. Our sensitive testing equipment identifies leaks in underground or concealed pipes that regular inspections might miss, protecting your property from gas buildup.

Commissioning Support

You cannot legally turn on a new commercial gas system without a successful purge and test. We facilitate the final step to get your heating or production lines running.

Our Expertise

Handling High-Pressure Environments

Testing commercial pipework isn’t like checking a home meter. It involves calculating pipe volume, purge velocity, and stabilization times. Safety Property engineers are mathematicians as well as technicians. We handle everything from 35mm copper lines to large steel industrial mains with absolute precision and safety.

Pricing

Transparent Pricing for Every Property

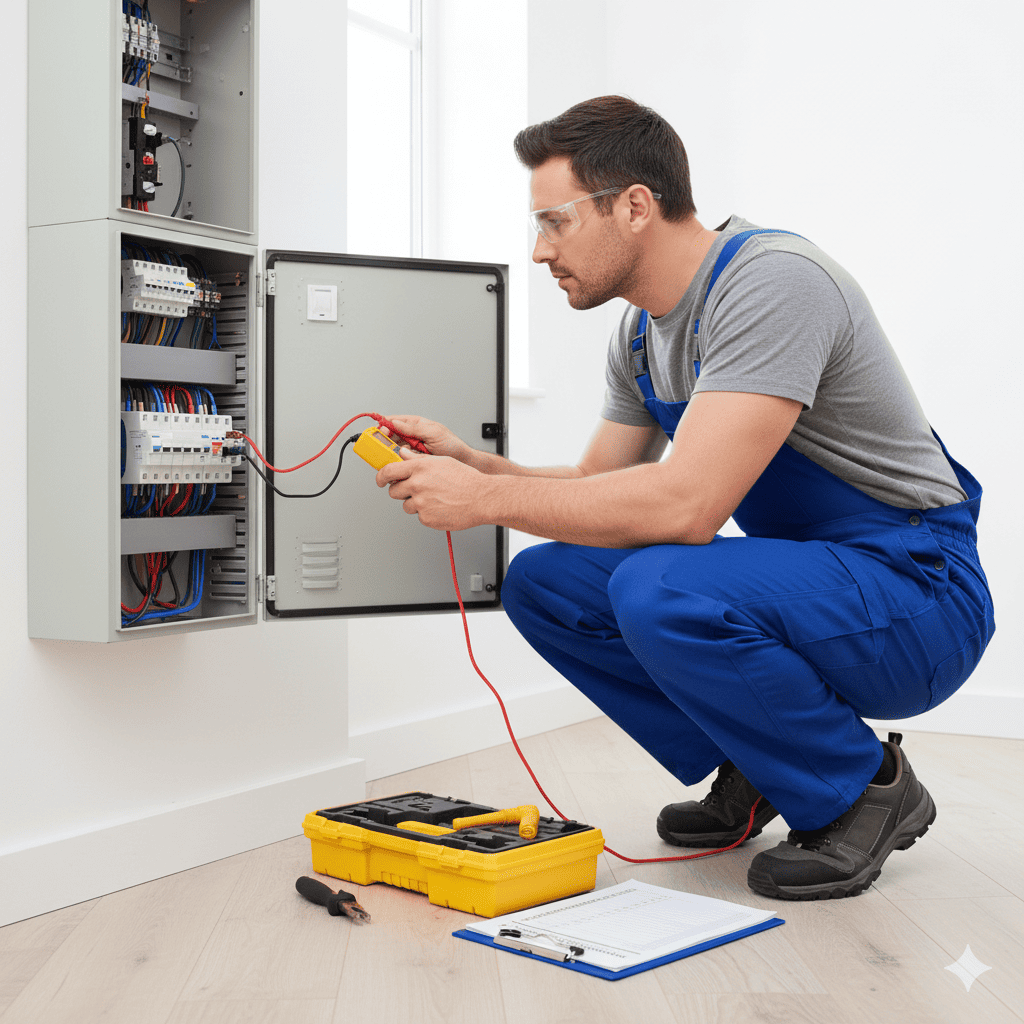

Competitive rates tailored to your property size. Electrical safety shouldn’t break the bank.

Studio / 1-Bed Flat

Standard Home (1-3 Bedrooms)

Additional Rooms

What is Testing and Purging?

Testing is the process of pressurizing the pipework (often with air or inert gas first) to check for leaks. We perform a “Strength Test” (for new pipes) to ensure they won’t burst, and a “Tightness Test” to ensure joints are sealed.

Purging is the critical safety step of swapping what is inside the pipe.

Direct Purging: Pushing air out using gas (to turn the system on).

Decommissioning: Pushing gas out using air or nitrogen (to make the pipe safe for cutting or removal).

This must be done at a specific speed to ensure the gas and air do not mix and create a flammable “slug.”

When Do You Need a CP16?

You don’t need a purge every day, but when you do, it is a critical safety operation that must be handled by specialists.

- New Installations

- System Extensions

- Suspected Leaks

- Demolition/Removal

Need Our Help ?

Don't Hesitate To Contact Us

Common Questions

FAQs About Gas Testing & Purging

This is a highly technical area of gas safety. Here are the answers to the questions we frequently get from contractors and facility managers.

Domestic pipes are small volume; they can often be purged simply by opening a test point. Commercial pipes (volume >0.035m³) hold massive amounts of gas. They require specific calculations (IGEM/UP/1) and purge hoses vented to a safe outside area.

It depends on the volume of the pipework. A large factory system might require a stabilization period of several hours before the actual test begins to account for temperature changes affecting pressure.

Absolutely not. Purging requires specialist calculation of "purge velocity." If done too slowly, gas and air mix (stratification), creating a bomb inside the pipe. Only Gas Safe engineers with specific commercial qualifications can do this.

This is done on new pipework only. We pressurize the pipes significantly higher than their normal operating pressure (using air) to ensure the physical pipes and welds are strong enough before any gas is introduced.